Specified width ft.

Ansi sheet metal tolerances.

And for machined components iso 27 68 fh can be used.

The following charts give typical astm and ansi steel sheet mechanical tolerance ranges.

Uncontrolled dimensions contain two different categories of tolerances.

Jis04081991 general dimensional tolerances for parts formed by press working from sheet metal foreign standard.

In the above example m and k has defined the tolerance.

Hr hot rolled cr cold rolled sheet metal gage guage size chart carbon steel sheets.

Up thru 3 over 3 allowable difference in length of diagonals inches maximum difference between aa and bb up thru 12 over 12 3 32 x width ft 2 9 64 x width ft 2 5 64 x width ft 2 7 64 x width ft 2 specified thickness in.

Flat bar hot rolled mild steel 3 4x 1 2 550 51 00 1 1 4 3 188 63 76 1 1 2 3 825 76 50 1 3 4 4 463 89 26 2 5 100 102 00 2 1 2 6 375 127 50 3 7 650 153 00 3 1 2 8 925 178 50 4 10 200 204 00 4 1 2 11 480 229 60 5 12 750 255 00 5 1 2 14 030 280 60 6 15 300 306 00 7 17 850 357 00 8 20 400 408 00 7 8x 1 2 975 59 50 1 1 4 3 719 74 38 1 1 2 4 463 89 26 1 3 4 5 206 104 10 2 5 950 119 00 2 1 4 6.

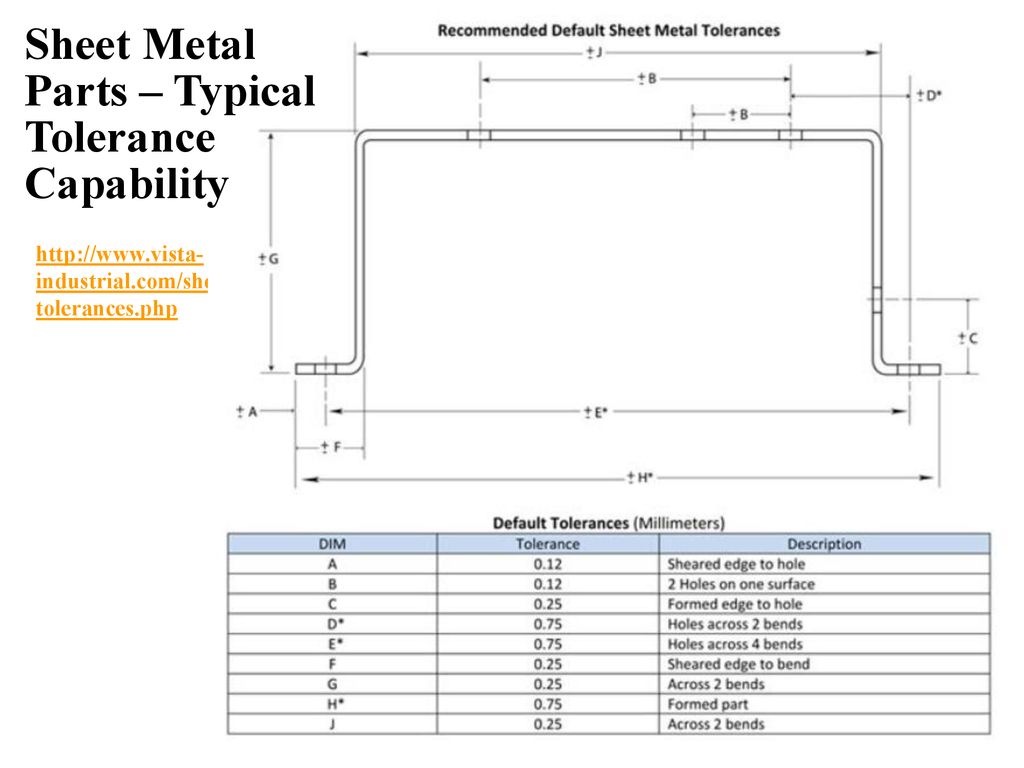

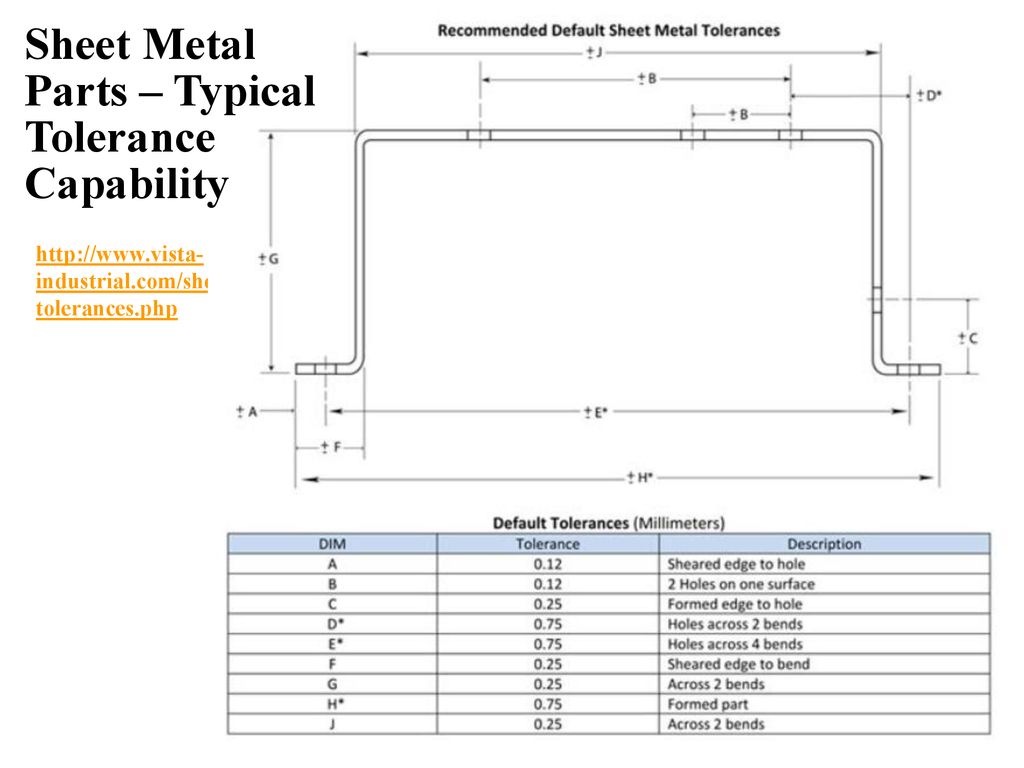

The resulting bend angle variation and sometimes the required adjustment to the flat layout contributes to the reason that machined parts typical tolerance of 0 002 in can routinely have tighter tolerances than precision sheet metal parts typical tolerance of 0 010 in.

General tolerance iso 2768 does not specify where to use these tolerances.

As per design requirements and manufacturing capability tolerance class is defined.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances.

Squareness tolerances flat sheet and plate specified length ft.

During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

For sheet metal parts iso 27 68 mk is used.

Plus and minus metal dimensions space dimensions allowable deviation from allowable deviation from specified specified dimension where.

1 all manufacturing tolerances used up to that point such as laser cutting tolerances welding tolerances and more 2 all bend tolerances for the entire part added together we call this an uncontrolled dimensions because there are additional tolerances to consider.